Service

With the delivery of a Graf Cleaning System, our service isn´t finished; in fact it just really starts.

We guarantee that all normal wear parts are supplied within latest 48 hours, normally even at the next business day (depending on the country).

We employ several service technicians, which execute planned but also unplanned maintenance works at the machines of our customers. We offer this for whole Europe and for the most other countries.

Our service technicians do the installation and takes care for the starting up and training of the operating persons.

Further we have installed in our facilities several automatic and manual wet blast systems and ultrasonic tanks, which are ready to operate.

So we can offer, even on a short term basis, to do wet blast trials with customer parts.

Additionally we work with a high-end and prcise measuring system, to measure e.g. an edge radius, or to judge a surface quality.

If a customer would like to test a machine in his plant without risks or if a purchase decision persists, then we always offer the possibilty to rent out certain machine types.

Graf Technik GmbH – Cleaning Systems

Your technologic leading partner for the design, manufacturing and worlwide sales of wet blast machines, ultrasonic tanks and washing systems.

Additional service benfits, like repair, maintenance, and renting of machines, sales of wear and spare parts, as well as working materials, complete our program.

Address

Graf-Technik GmbH

Max-Eyth-Straße 23

DE 70736 Fellbach-Oeffingen

Germany

Tel.: +49 / 711 / 633447-0

Fax: +49 / 711 / 633447-25

Our most important contact persons

Management and Sales of machines:

Heiko Graf

Tel.: +49 / 711 / 633447-17

Fax: +49 / 711 / 633447-27

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Technical Support and Sales:

Andreas Umlauf

Tel.: +49 / 711 / 633447-11

Fax: +49 / 711 / 633447-25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Alexander Reimer

Tel.: +49 / 711 / 633447-15

Fax: +49 / 711 / 633447-25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Purchase Orders / Adminstration / Office:

Renate Merwerth

Tel.: +49 / 711 / 633447-10

Fax: +49 / 711 / 633447-25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Elke Holzwarth

Tel.: +49 / 711 / 633447-12

Fax: +49 / 711 / 633447-25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Service / Maintenance:

Ivica Malinovski

Tel.: +49 / 711 / 633447-20

Fax: +49 / 711 / 633447-25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Gabriel Livint

Tel.: +49 / 711 / 633447-20

Fax: +49 / 711 / 633447-25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Arpad Nemeth

Tel.: +49 / 711 / 633447-20

Fax: +49 / 711 / 633447-25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Imprint

Angaben nach § 5 TMG (Telemediengesetz)

Graf-Technik GmbH

Max-Eyth-Straße 23

DE-70736 Fellbach

Telefon: +49 / 711 / 633 447 - 0

Fax: +49 / 711 / 633 447 - 25

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Geschäftsführung: Heiko Graf, Dieter Graf

USt.-ID: DE147322045

Verantwortliche Redaktion im Sinne des TMG

Heiko Graf

Konzeption, Design & Realisation

Colin Rombold Medienproduktion · www.colin-rombold.de · cr[at]colin-rombold.de

Copyright

Graf-Technik GmbH, Max-Eyth-Straße 23, DE-70736 Fellbach.

Alle Rechte vorbehalten.

Urheberrecht

Alle auf unserer Website erscheinenden Texte, Fotografien, Grafiken sowie das Layout dieser Website unterliegen dem Urheberrecht. Jegliche Nutzung und Bearbeitung ohne unsere schriftliche Erlaubnis ist nicht gestattet.

Verlinkung

Wir weisen ausdrücklich darauf hin, dass wir keinen Einfluss auf den Inhalt anderer Websites haben, auf die durch Links von dieser Website verwiesen wird. Wir machen uns die Inhalte dieser Websites nicht zu eigen.

Quellenverweis

Die Texte dieses Angebotes sind, sofern nicht anders angegeben, selbst erstellt.

Datenschutz

Die Nutzung unserer Webseite ist in der Regel ohne Angabe personenbezogener Daten möglich. Soweit auf unseren Seiten personenbezogene Daten (beispielsweise Name, Anschrift oder eMail-Adressen) erhoben werden, erfolgt dies, soweit möglich, stets auf freiwilliger Basis. Diese Daten werden ohne Ihre ausdrückliche Zustimmung nicht an Dritte weitergegeben. Wir weisen darauf hin, dass die Datenübertragung im Internet (z.B. bei der Kommunikation per E-Mail) Sicherheitslücken aufweisen kann. Ein lückenloser Schutz der Daten vor dem Zugriff durch Dritte ist nicht möglich. Der Nutzung von im Rahmen der Impressumspflicht veröffentlichten Kontaktdaten durch Dritte zur Übersendung von nicht ausdrücklich angeforderter Werbung und Informationsmaterialien wird hiermit ausdrücklich widersprochen. Die Betreiber der Seiten behalten sich ausdrücklich rechtliche Schritte im Falle der unverlangten Zusendung von Werbeinformationen, etwa durch Spam-Mails, vor.

The Company / Our Philosophy

Since 1984 the company Graf Technik GmbH is leading in the manufacturing and the worldwide sales of wet blast systems, ultrasonic and washing systems.

The applications of Graf cleaning systems are widely spread, especially of our wet blast systems:

Cleaning of extrusion dies for the aluminium industry, injection moulds from the plastic industry and moulds for the rubber industry.

Cleaning of parts for the semi conductor and optical industry, and parts from vacuum pumps are further important applications since many years.

Further applications are surface finishing of components, deburring of piston and housing parts, cleaning of motor / gear box components.

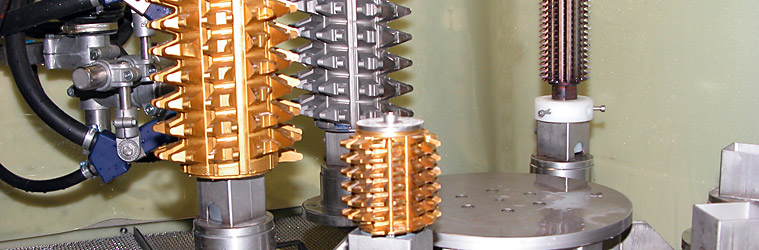

In the last 20 years, the defined edge honing of cutting edges of precision tools, as well as the activation and polishing of PVD/CVD-coatings of cutting tools have tremendously moved into the forground.

We have acknowledged the changes in the application areas from the beginning by inventing, redesigning and optimizing especially of our automatic wet blast systems.

We offer our customers the complete service by our team from one source:

Starting with the design, manufacturing, worldwide sales, installation, starting up until the supply with wear / spare parts and working material.

All our machines are made in a rigid, solid stainless steel construction. At our wet blast systems all critical core components and assembly groups had been developed and are manufactured by us. So we can ensure the longest possible lifetime and the highest availability of the machine.

Product Overview

Wear and spare parts

At all of our Standard and small series machines we use exclusively reliable and problem free components and assembly groups.

When machines are newly developed, we only assemble similiar, rsp. modified existing units, according to the application.

The advantage for our customers is the easy recognition and our rapid delivery capacity of wear and spare parts.

When special gear drives or motors are built in, we recommend our customers to stock certain important parts.

Almost all motors / gear drives, which we have assembled in the last 10 – 15 years, we do have on our stock.

The parts and components, which are used at our machines, like wet blast pumps, blast guns, adaptors, cyclones, hoses, etc., consist of extremly wear resistant materials.

Therefore those parts have a very long lifetime.

It is very imortant for us, that all machines offer good maintenance access in service cases. Therefore all machines are equipped with min. 2 sufficient big doors.

The components are assembled in a way, that they can be exchanged fast and easy. Assembly groups, like oscillation unit, turntable drive, etc. are always mounted outside of the wear zones, e.g. on the machine roof, so that they can work unproblematic.

Even if a part has to be changed at those units it can be done with a good access.

By using those high-quality materials, and our experience of 28 years in manufacturing cleaning systems, we have reached a quality level, which we judge as absolutely error low.

We keep on our stock a huge amount of all different wear and spare parts, which can be supplied immediately.